Description:

We design, construct and deliver our bridges, platforms, staircases and ladders according our customer’s requirements. We supply simple stairs and staircases and flights with one or several platforms as well as complete staircases for several floors.

We supply standard ladders with 300, 400 or 500 mm width. The standard rungs have two perforation rows.

Application:

Bridges are generally used to support machines like mixers or DAF tanks. In that case the bridges are also used for maintenance works, as well.

Ladders will be used at our machines and to get on platforms at tanks and silos. There are several constructions and materials available. We offer ladders made of steel galvanized or powder coated, made of stainless steel and aluminum. For special applications we even offer special stainless steel alloys like Duplex, Hastelloy and Incolloy materials.

Shaft ladders can be used for shaft applications. Shaft ladders are not available made of aluminum, due to the fact that aluminum is generally not recommendable in explosion proof areas, because of the low fusion point of aluminum.

Bitte wählen Sie Ihre Sprache aus dem Pull-Down-Menü

Please choose your language from the pull-down-menu

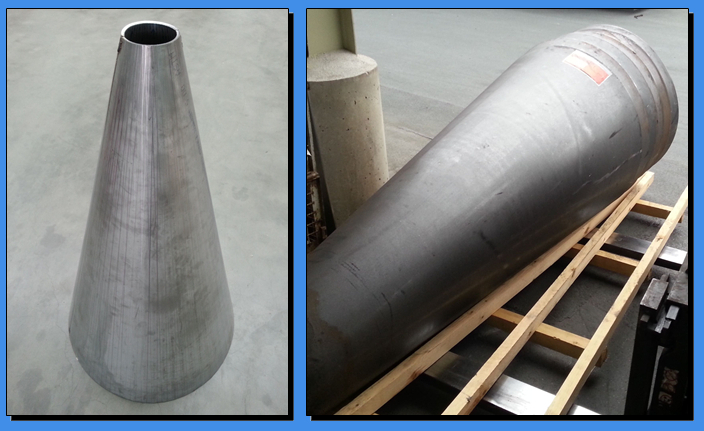

Description:

We design and manufacture symmetrical and asymmetrical cones and conical shapes.

Application:

We usually manufacture cone tubes for our own products of tubes or injectors for pump stations or pressure vessels.

Description:

We design and manufacture several kinds of tubes up to a diameter of 3 m and a sheet thickness of 30 m.

Application:

We generally use the manufacturing of tubes for our own manufacturing of vessels and tanks.

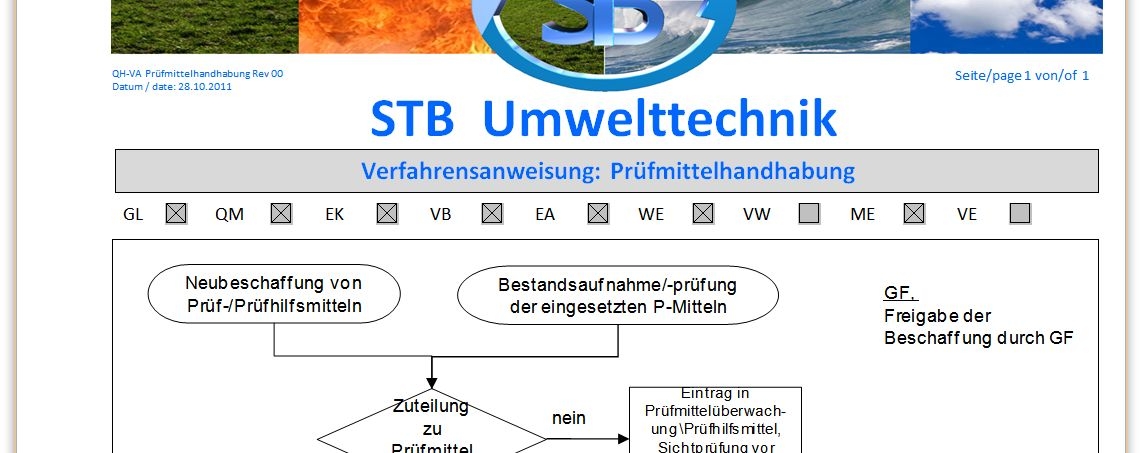

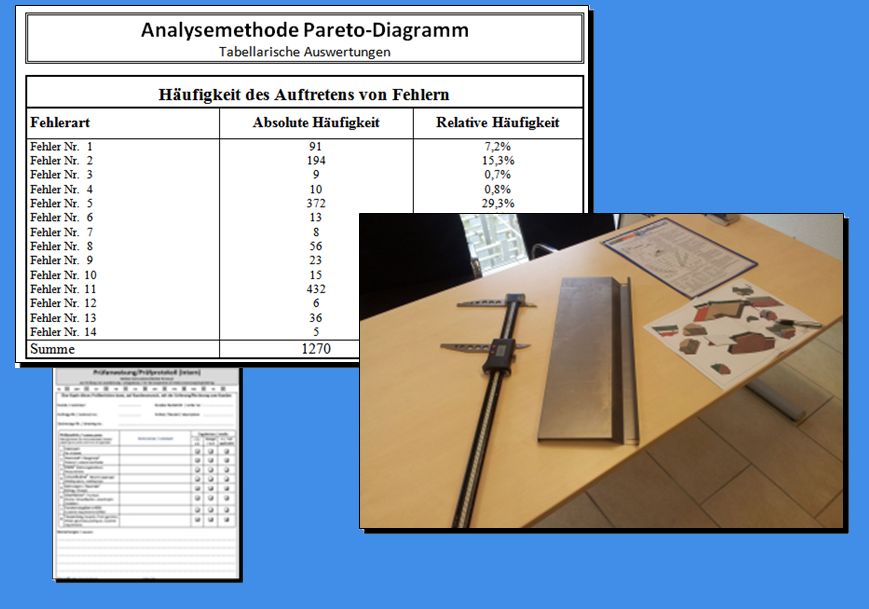

Description:

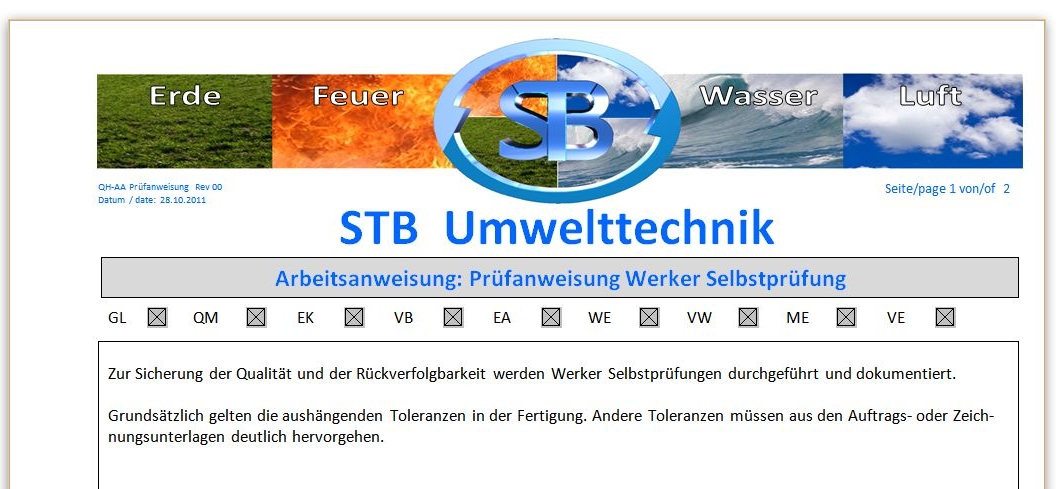

We carry out random tests for all products of our scope of supply. We use X-ray tests to examine the welding of specific products like pressure tanks.We cooperate with TÜV/MOT for external examinations.

Application:

We provide all necessary or essential measuring equipment to ensure the best possible tests during the manufacturing process.

We continously carry out emploee self control tests.

Since 2015 we additional have implemented a continous welding process inspection.Our welding engineer carries out a welding procedure sheet for all welding processes.

English (UK)

English (UK)  Deutsch

Deutsch